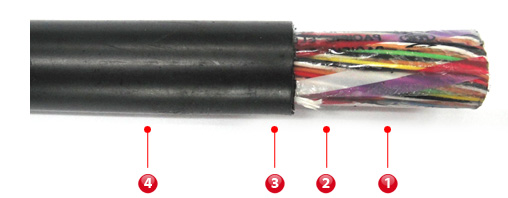

F/S-JF-LA Cable

Asia Pacific Wire & Cable Corp Ltd.

The cable is foam-skin polyethylene insulated, quad unit type, jelly filled, laminated sheath telephone cable which is designed for use in subscribers distribution.It features excellent blocking performance for water penetrated and can be installed aerially or underground in ducts.

FOAM-SKIN POLYETHYLENE INSULATED JELLY FILLED LAMINATED SHEATH CABLES (F/S-JF-LAP)

0.4mm ; 0.5mm ; 0.65mm data sheet

| Conductor diameter (mm) | Pairs(P) | Insulation Nom. (mm) | Cable core approx. (mm) | Laminated sheath thickness Nom. (mm) | Overall diameter approx. (mm) | Cable approx (kg/m) | Cable length (m) |

|---|---|---|---|---|---|---|---|

| 0.4 | 10 | 0.13 | 6 | 1.7 | 10 | 0.10 | 500 |

| 20 | 8 | 1.7 | 12 | 0.18 | 500 | ||

| 30 | 9 | 1.7 | 13 | 0.23 | 500 | ||

| 50 | 11 | 1.7 | 15 | 0.33 | 500 | ||

| 100 | 15 | 1.7 | 19 | 0.51 | 500 | ||

| 200 | 21 | 1.7 | 25 | 0.90 | 500 | ||

| 300 | 25 | 1.9 | 29 | 1.36 | 500 | ||

| 400 | 29 | 2.0 | 34 | 1.70 | 500 | ||

| 600 | 35 | 2.2 | 40 | 2.46 | 500 | ||

| 0.5 | 10 | 0.15 | 7 | 1.7 | 11 | 0.14 | 500 |

| 20 | 9 | 1.7 | 13 | 0.23 | 500 | ||

| 30 | 11 | 1.7 | 15 | 0.30 | 500 | ||

| 50 | 13 | 1.7 | 17 | 0.41 | 500 | ||

| 100 | 18 | 1.7 | 22 | 0.74 | 500 | ||

| 200 | 24 | 1.8 | 28 | 1.30 | 500 | ||

| 300 | 30 | 2.0 | 35 | 1.98 | 500 | ||

| 400 | 34 | 2.1 | 39 | 2.60 | 500 | ||

| 600 | 41 | 2.3 | 47 | 3.62 | 500 | ||

| 0.65 | 10 | 0.20 | 8 | 1.7 | 12 | 0.18 | 500 |

| 20 | 11 | 1.7 | 15 | 0.33 | 500 | ||

| 30 | 13 | 1.7 | 17 | 0.43 | 500 | ||

| 50 | 16 | 1.7 | 20 | 0.63 | 500 | ||

| 100 | 23 | 1.8 | 27 | 1.10 | 500 | ||

| 200 | 31 | 2.0 | 36 | 2.10 | 500 | ||

| 300 | 37 | 2.2 | 42 | 3.15 | 500 | ||

| 400 | 42 | 2.3 | 4.00 | 48 | 500 | ||

| 600 | 51 | 2.6 | 57 | 5.80 | 345 |

| Electrical properties | |

|---|---|

| Conductor resistance (Ω/km) | 0.4mm:nom. 139.0、max. 147.5 0.5mm:nom. 88.7、max. 93.5 0.65mm:nom. 52.5、max. 56.5 |

| Dielectric strength | Between each insulation conductor and ground:D.C. 500V/1min. or A.C. 350V/1min., the cable shall be normal. Between aluminum and ground:A.C. 1000V/1 min., the cable shall be normal. |

| Insulation resistance | min. 5,000MΩ-km |

| Mutual capacitance | ≧50P:max. ave. 55nF/km ≦ 30P:max. ave. 60nF/km. |

| Near end cross-talk (40KHz) | 200P to 600P, cable length more than 300m: (1) The second worse value of each unit is not less than 58.5dB, the minimum value of each unit which is not less than 50dB allows only one. (2) The minimum average of each reel is not less than 62dB. (3) The total average for all units of each reel is not less than 66dB. <100P, cable length more than 300m: (1) The minimum value of each reel is not less than 58.5dB. (2) The total average of each reel is not less than 66dB. |

| Far end cross-talk(160KHz) | Cable length 1000m: (1) m-1.28×S≧55dB/km. (2) Individual minimum value is not less than 38dB/km. m:average,S:standard deviati |

| Aluminum resistance | Max.62.5/D Ω/km (D is the inside diameter of laminated aluminum sheath). |

| Spark test of sheath | D.C. 3000V/1min. or A.C. 2000V/1min., the cable shall be normal. |