Application

High shielded cable:Applied to communications along the electrified wire of railway, cable can be distinguished to jelly filled type and air filled type.

Wayside cable:Applied to communications along the track of high speed railway and between track and the central office.

Construction

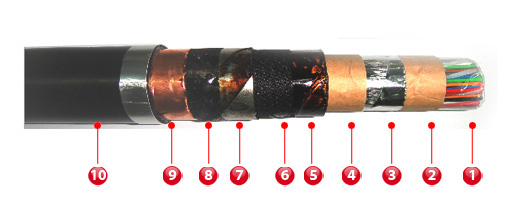

Air filled type high shielded cable

Cable core

Conductor: Solid annealed copper

Insulation: Polyethylene Quadding: Color polyester tape

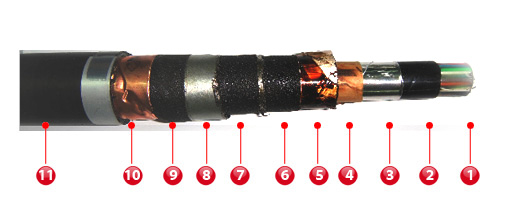

Jelly filled type high shielded cable

Cable core

Conductor: Solid annealed copper

Insulation: Polyethylene Quadding: Color polyester tape

Filled jelly: Petroleum jelly

Covering: Mylar tape

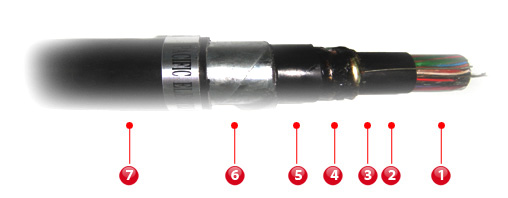

Wayside cable

Cable core

Conductor: Solid annealed copper

Insulation: Polyethylene

Wrapping: Fire proofing tape (Suitable for Fire resistance cable)

Ouadding

Covering: Mylar tape

Property

High shielded cable.

- Aluminum sheath and high magnetic permeability metal tape shielded structure with low induced voltage.

- Comply with the European DEMKO certification.

- Prevent communication line interference from electromagnetic induction.

- Air filled type high shielded cable with better air sealing of cable.

- Jelly filled type high shielded cable with better water penetration properties.

Wayside cable

- Comply with REA PE-89 electrical properties and water penetration properties.

- Sheath of low smoke free halogen, cable complies with the requirements of IEC 61034, IEC60754 and NES 713.

- Flame retardant cable complies IEEE 383 or IEC 60332-3 test requirements.

- Prevent electromagnetic interference of high voltage line.

- Fire resistance cable complies IEC60331 test requirements.

Specification

Air filled type high shielded cable

| Conductor diameter and pairs | onductor diameter nom. (mm) | Conductor diameter (mm) | Cable coredia meter (mm) | Aluminum sheath thickness (mm) | Outer sheath thickness (mm) | Overall diameter approx. (mm) |

|---|---|---|---|---|---|---|

| 0.9×68P + 1.2×34P |

0.9 | 38.6 | 2.5 | 0.5 | 2.5 | 54.8 |

| 1.2 |

Jelly filled type high shielded cable

| Conductor diameter and pairs | onductor diameter nom. (mm) | Conductor diameter (mm) | Cable coredia meter (mm) | Aluminum sheath thickness (mm) | Outer sheath thickness (mm) | Overall diameter approx. (mm) |

|---|---|---|---|---|---|---|

| 0.9×28P | 0.9 | 18.0 | 2.5 | 0.5 | 2.5 | 40.1 |

| 0.9×54P | 0.9 | 24.5 | 2.5 | 0.5 | 2.5 | 46.4 |

ELECTRICAL PROPERTIES

| Conductor resistance | Conductor diameter (mm) | 0.9 | 1.2 | ||

|---|---|---|---|---|---|

| Max. ave.(Ω/km) | 27.4 | 15.4 | |||

| Max.(Ω/km) | 29.0 | 16.3 | |||

| Conductor resistance unbalance | max. 1% | ||||

| High volatge test | 500V(R.M.S) for 1 min.,the cable shall be normal. | ||||

| Insulation resistance | min. 20,000 MΩ-km | ||||

| Mutual capacitance (nF/km) | Norminal | Minimum | Maximum | ||

| All cables | 90% of cables | 90% of cables | All cables | ||

| 38.5 | 35.2 | 36.5 | 40.5 | 41.8 | |

| Capacitance unbalance(pF/500M) | Item | Limits for 90% of cable | Limits for remaining 10% of cable | ||

| Ave. | Maximum | Ave. | Maximum | ||

| Between pairs in quad | 40 | 160 | 55 | 240 | |

| Between pairs in adjacent quads | 20 | 110 | 20 | 110 | |

| Between any pair and earth | 160 | 650 | 220 | 950 | |

| Screening factor:According to VDE 0472 1983 | Field strength(V/km)/td> | Screening factor | |||

| 60Hz | 800Hz | ||||

| 50 | 0.15 | 0.0025 | |||

| 100 | 0.08 | 0.0025 | |||

| 300 | 0.06 | 0.0025 | |||

| 500 | 0.08 | 0.0025 | |||

| 1000 | 0.10 | 0.0025 | |||

Wayside cable

| Conductor diameter & pairs | onductor diameter nom. (mm) | Cable diameter approx. (mm) | Inner sheath thickness nom. (mm) | Steel tape thickness nom. (mm) | Outer sheath thickness nom. (mm) | Overall diameter approx. (mm) |

|---|---|---|---|---|---|---|

| 0.9×60P | 0.9 | 26.4 | 1.9 | 0.5 | 2.5 | 45.5 |

| 0.9×70P | 0.9 | 28.0 | 1.8 | 0.5 | 2.5 | 47.6 |

ELECTRICAL PROPERTIES

| Conductor resistance | MAX. 29.0Ω/km |

|---|---|

| Insulation resistance | MIN. 5000MΩ-km |

| Dielectric strength | D.C. 500V/1 min. (core-core) |

| Mutual capacitance | MAX. 60nF/km |

| Screening factor | 0.6 (Field strength 50V/km at 50,60Hz) |