Application

Applied to in-building backbone. PEWC indoor distribution bundle type optical cables offer maximum 96 fibers count with single or multi cable subunit of 900 μm tight-buffered fibers which are color coded for easy identification. Cables provide flame retardant characteristics and flexible thermoplastic jacket provides excellent handling characteristics. Full dielectric construction, no grounding required.

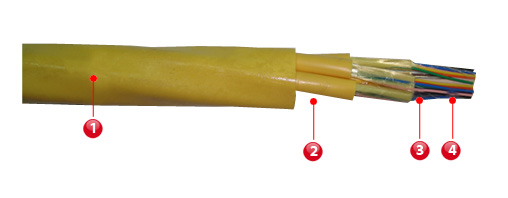

Construction

Indoor Fiber Optics Cable (Distribution Bundle type)

Property

- Available in single mode fiber and multi-mode fiber.

- CSM: Glass fiber reinforced plastic rod(FRP) with oversheathing could provide efficient tension for cable.

- 6/12 Cable subunits: Tight buffer fibers、Aromatic yarn and coloured flame retardant PE sheath

- Stranding: Cable subunits would be stranded around the CSM.

- Peripheral Strength Element: Aramid yarns is used.

- Ripcord:Nylon thread or Aramid yarn for easily stripping of the sheath.

- LSZH PE sheath: Low Smoke Zero Halogen sheath with Flame retardant characteristics.

Specification

24C、48C、96C,Detail specification as following :

Construction

| No. of Fibers (C) | 24 | 48 | 96 |

|---|---|---|---|

| Out sheath thickness(mm) | 1.0 | 1.0 | 1.0 |

| Cable Diameter(mm) | 15.8 | 18.5 | 24.0 |

| Cable weight(App.)(kg/m) | 0.20 | 0.26 | 0.48 |

Application

| Temperature Range | Minimum Bending Radius |

|---|---|

| Transportation&Storage: -30~+60℃ Installation: 0~+60℃ Operation: -30~+60℃ |

Under Maximum Tension : 20×Cable diameter Without Tension: 10×Cable diameter |

Mechanical and Environmental Characteristics:

| Test | Test Standard | Specified Value | Acceptance Criteria |

|---|---|---|---|

| Tensile Loading and Bending Test | EIA-455-33A | Mandrel diameter: 20D (D = cable diameter) for 150m Tensile load: 135/160kgf for 10 minutes |

(1) Attenuation Increment≦ 0.2 dB (Single-mode) Increment≦ 0.3 dB (Multi-mode) (2) No jacket cracking and fiber breakage |

| Cyclic Flexing Test | TIA/EIA-455-104A | Sheave diameter:20D (D=cable diameter) No. of flexing cycles: 25 cycles Flexing speed: 30 cycles/minute Flexing angle: 90°/cycle |

|

| Repeated Impact Test | TIA/EIA-455-25B | No. of impact cycles: 20 cycles Cycle speed:30±1 cycles/min. |

|

| Cable Twist Test | TIA/EIA-455-85A | Cable length twisted: 2m No. of twist cycles: 10 cycles for 10 min. Twist angle: ±180°/cycle |

|

| Pinch resistance | TIA/EIA-455-41A | Applied load: 1 kgf/mm Duration of loading: 10 minutes Load length: more than 100 mm Compressive speed: 2.54 mm/min. |

|

| Fire Performance | lEEE 383 or JIS C 3521 | Ribbon burner | The maximum flame extends should less than 1.8m |

This section shall be performed at 1550nm wavelength.

Optical Characteristics

| 4.1 Maximum Attenuation | |

|---|---|

| Wavelength | Attenuation(dB/km) |

| 1260nm | ≦ 0.45 |

| 1310nm | ≦ 0.40 |

| 1383nm±3nm | ≦ 0.35 |

| 1550nm | ≦ 0.25 (90%) ≦ 0.30 (100%) |

| 1625nm | ≦ 0.35 |

| 4.2 Chromatic Dispersion | |

|---|---|

| Wavelength | Specification (ps/km-nm) |

| 1260nm | ≦ 6.21 |

| 1310nm | ≦ 1.14 |

| 1383nm | ≦ 7.05 |

| 1550nm | ≦ 18.21 |

| 1625nm | ≦ 22.31 |

| 4.3 Polarization Mode Dispersion , PMD | |

|---|---|

| Individual Polarization Mode Dispersion | 0.2 ps /√km |

| Linked Polarization Mode Dispersion,PMDQ 20 Cables(M=20) 0.01% Probability level(Q=0.01%) |

0.1ps /√km |

| 4.4 Cut-off Wavelength of Cabled:Less than 1260nm. |

|---|

| 4.5 Mode Field Diameter | |

|---|---|

| 1310nm | 9.0~9.4μm±0.4μm |

| 1550nm | 10.0~10.7μm±0.7μm |

Identification

| 6/12 Cable subunits | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5.1.1 Identification of Cable subunit | Fiber No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Bule | Yellow | Green | Red | Violet | White | Brown | Black | Aqua | Orange | Pink | Grey | |

| 5.1.2 Cable subunit colours: | Unit No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Color | Bule | Yellow | Green | Red | Violet | White | Brown | Black |

| Outer sheathColor |

|---|

| Single mode: Yellow 62.5μm Multi-mode: Grey 50μm Multi-mode & L50 Multi-mode: Orange |

| 5.4 Sheath Marking |

|---|

| PACIFIC 《year of manufacture》《Cable type and fiber count》《length marking in meter》 |

Packing

Metal or Wooden drums with protection.

Delivery Lengths

Standard delivery length is 2000 meters.