Application

LSZH cables are designed for indoor and outdoor use. Dry core design for excellent water blocking performance and easier handling. The outer jacket uses a flame-retardant Low Smoke Zero-Halogen material. Applied to connection between outside plant stranded loose tube cable and terminal distribution frame in central office.

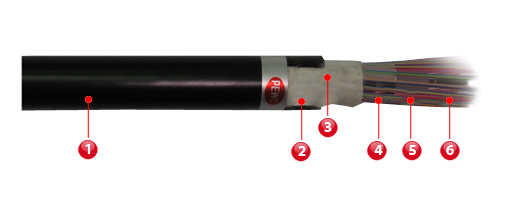

Construction

Slotted Ribbon Flame Retardant Cable

Property

- CSM: Could provide efficient tension for cable.(Option)

- PE Slotred Core: HD polyethylene extrusion.

- Stranding: Accommodate the 4-fiber ribbons into grooves of slotted core.

- Outer sheath: (Option)

- Ripcord: Aramid yarn thread allows easy sheath removal.

- Outer Sheath: (Option)

Galvanized steel wire

FRP Rod (Non-metallic type for power line system)

LSZH LAP sheath: Low Smoke Zero Halogen Laminated Aluminum sheath for moisture barrier and Flame retardant characteristics.

LSZH PE sheath: Low Smoke Zero Halogen sheath for Flame retardant characteristics.

Specification

4C~300C,Detail specification as following :

Construction

| No. of Fibers | Unit | 4~100 | 200心 | 300心 |

|---|---|---|---|---|

| CSM diameter | NO | 25 | 50 | 75 |

| CSM diameter | mm | 2.6 | 2.6 | 2.6 |

| Slotted Core diameter | mm | 9 | 14 | 16 |

| Slotted core No. | mm | 5 | 10 | 15 |

| LAP outer sheath thickness | mm | 1.7 | 1.7 | 1.7 |

| Cable Diameter | mm | 14 | 19 | 21 |

| Cable weight(App.) | kg/m | 0.12 | 0.25 | 0.33 |

Application

| Temperature Range | Minimum Bending Radius |

|---|---|

| Transportation&Storage: -30~+60℃ Installation: 0~+60℃ Operation: -30~+60℃ |

Under Maximum Tension : 20×Cable diameter Without Tension: 10×Cable diameter |

Mechanical and Environmental Characteristics:

| Test | Test Standard | Specified Value | Acceptance Criteria |

|---|---|---|---|

| Tensile Loading and Bending Test | IEC 60794-1-E1 | Mandrel diameter: 20D (D = cable diameter) for 12m length Tensile load: 100C: 200kgf for 30 minutes 200C/300C:273 kgf for 30 minutes |

(1) Attenuation Increment≦ 0.2 dB (2) No jacket cracking and fiber breakage |

| Cyclic Flexing Test | TIA/EIA-455-104A | Sheave diameter:20D (D=cable diameter) No. of flexing cycles: 25 cycles Flexing speed: 30 cycles/minute Flexing angle: 90°/cycle |

|

| Repeated Impact Test | TIA/EIA-455-25B | No. of impact cycles: 20 cycles Cycle speed:30±1 cycles/min. |

|

| Cable Twist Test | TIA/EIA-455-85A | Cable length twisted: 4m No. of twist cycles: 10 cycles for 10 min. Twist angle: ±180°/cycle |

|

| Pinch resistance | TIA/EIA-455-41A

|

Applied load: 4.54kgf/mm Duration of loading: 10 minutes Load length: more than 100 mm Compressive speed: 2.54 mm/min. |

|

| Water Penetration | TIA/EIA-455-82B/ IEC 60794-1-2F5B | Length of specimen: 100C: 3.1m 200/300C: 6.1m Height of pressure head: 1m Test time: 24 hours |

No leakage through the open cable end |

This section shall be performed at 1550nm wavelength.

Optical Characteristics

| 4.1 Maximum Attenuation | |

|---|---|

| Wavelength | Attenuation(dB/km) |

| 1260nm | ≦ 0.45 |

| 1310nm | ≦ 0.40 |

| 1383nm±3nm | ≦ 0.35 |

| 1550nm | ≦ 0.25 (90%) ≦ 0.30 (100%) |

| 1625nm | 0.35 |

| 4.2 Chromatic Dispersion | |

|---|---|

| Wavelength | Specification (ps/km-nm) |

| 1260nm | 6.21 |

| 1310nm | 1.14 |

| 1383nm | 7.05 |

| 1550nm | 18.21 |

| 1625nm | 22.31 |

| 4.3 Polarization Mode Dispersion , PMD | |

|---|---|

| Individual Polarization Mode Dispersion | 0.2 ps /√km |

| Linked Polarization Mode Dispersion,PMDQ 20 Cables(M=20) 0.01% Probability level(Q=0.01%) |

0.1ps /√km |

| 4.4 Cut-off Wavelength of Cabled:Less than 1260nm. |

|---|

| 4.5 Mode Field Diameter | |

|---|---|

| 1310nm | 9.0~9.4μm±0.4μm |

| 1550nm | 10.0~10.7μm±0.7μm |

Identification

| 5.1 Ribbon code | ||||

|---|---|---|---|---|

| Ribbon No. | Fiber NO. Color | |||

| 1 | 2 | 3 | 4 | |

| I | Bule | White | White | Pink |

| II | Yellow | White | White | Pink |

| III | Green | White | White | Pink |

| IV | Red | White | White | Pink |

| V | Violet | White | White | Pink |

| 5.2 Configuration of Ribbons | |||||

|---|---|---|---|---|---|

| Slot No. | 200C、300C Ribbon No. | ||||

| 1 | 2 | 3 | 4 | 5 | |

| 4 | I | ||||

| 8 | I | II | |||

| 12 | I | II | III | ||

| 16 | I | II | III | IV | |

| 24 | I、II | III | IV | V | I |

| 48 | I~V | I~V | I~II | ||

| 72 | I~V | I~V | I~V | I~III | |

| 100 | I~V | I~V | I~V | I~V | I~V |

| Slot No. | 200C、300C Ribbon No. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

| 200 心 | I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

|||||

| 300 心 | I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

I ~ V |

| 5.3 Sheath Color: Black |

|---|

| 5.4 Sheath Marking |

|---|

| PACIFIC 《year of manufacture》《Cable type and fiber count》《length marking in meter》 |

Packing

Metal or Wooden drums with protection.

Delivery Lengths

Standard delivery length is 2000 meters.